Timber LVL formwork has gained popularity as a cost-effective solution for construction projects. This article explores the various aspects of timber LVL formwork, including its definition, manufacturing process, financial benefits, environmental impact, durability, and challenges. By understanding the advantages and limitations of timber LVL formwork, contractors and builders can make informed decisions regarding its implementation.

Understanding Timber LVL Formwork

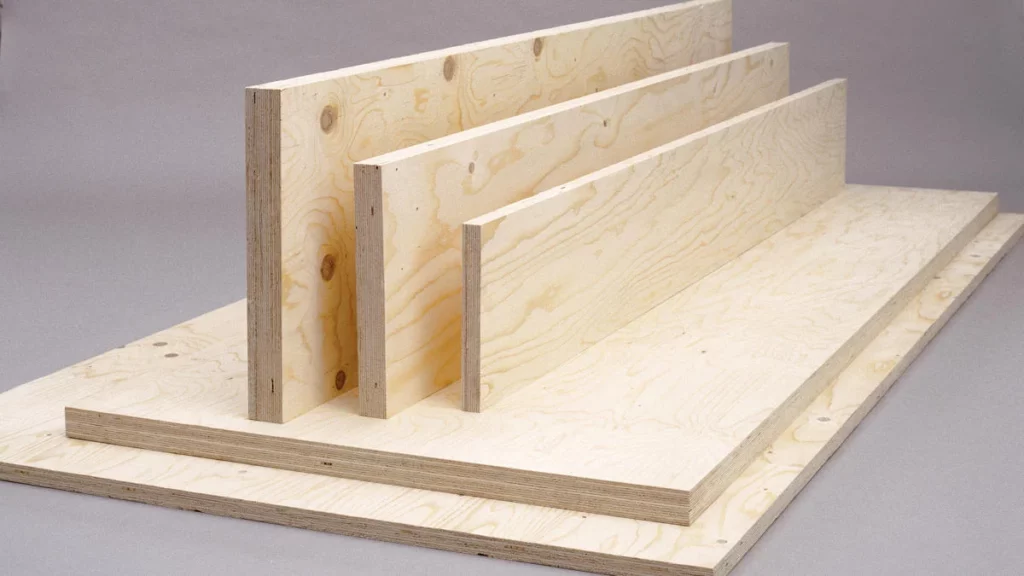

Timber LVL formwork is a construction technique that utilizes laminated veneer lumber (LVL) sheets for creating temporary molds or frameworks. These frameworks support wet concrete until it solidifies and can be self-supporting.

Lvl timber formwork plays a crucial role in the construction industry, providing a cost-effective and efficient solution for creating structures with complex shapes and designs. It offers builders the flexibility to mold concrete into various configurations, allowing for the realization of unique architectural visions.

Definition and Characteristics of Timber LVL Formwork

Timber LVL formwork consists of LVL sheets that are lightweight, strong, and easy to handle. They are designed to withstand the weight and pressure of wet concrete, ensuring the structural integrity of the final construction. Additionally, timber LVL formwork is known for its versatility and compatibility with various architectural designs.

Furthermore, timber LVL formwork is environmentally friendly, as LVL is often sourced from sustainably managed forests. This sustainable aspect appeals to environmentally conscious builders and developers looking to reduce their carbon footprint and promote eco-friendly construction practices.

The Manufacturing Process of Timber LVL Formwork

The manufacturing process of timber LVL formwork involves bonding several veneer layers together with adhesives. The layers are arranged in a parallel orientation, resulting in a strong and stable material that can withstand heavy loads.

During the manufacturing process, quality control measures are implemented to ensure that the LVL sheets meet industry standards for strength and durability. This attention to detail in production contributes to the reliability and performance of timber LVL formwork on construction sites, where safety and efficiency are paramount.

The Financial Benefits of Using Timber LVL Formwork

Implementing timber LVL formwork offers several financial advantages over traditional formwork methods. In addition to the cost savings, there are several other benefits that make timber LVL formwork a preferred choice in the construction industry.

Learn how to install lvl beam on: LVL Beam Installation Best Practices and Tips

Material Cost Comparison: Timber LVL vs. Traditional Formwork

When comparing material costs, timber LVL formwork proves to be a cost-effective solution. LVL sheets are not only affordable but also offer durability and strength, making them a long-term investment. The sustainability of timber LVL formwork is another factor to consider, as it aligns with eco-friendly construction practices, which can have a positive impact on project certifications and overall reputation.

Labor Cost Savings with Timber LVL Formwork

Timber LVL formwork is known for its ease of use and quick assembly. The lightweight nature of LVL sheets simplifies the installation process, reducing the need for extensive labor. This efficiency not only saves time but also minimizes the risk of on-site injuries, contributing to a safer working environment. Additionally, the versatility of timber LVL formwork allows for customization and adaptability, catering to various project requirements without incurring additional labor costs.

The Environmental Impact of Timber LVL Formwork

In addition to its cost-effectiveness, timber LVL formwork also offers environmental benefits, making it a sustainable choice for construction projects.

Timber Laminated Veneer Lumber (LVL) formwork not only provides structural support during construction but also contributes to the preservation of forests and ecosystems. The production of timber LVL formwork involves the use of wood from responsibly managed forests, which helps maintain biodiversity and supports the livelihoods of local communities. By choosing timber LVL formwork, builders are actively participating in sustainable forestry practices that ensure the long-term health of our planet.

Sustainability of Timber LVL Formwork

Timber LVL formwork is made from sustainably sourced and responsibly managed wood. By utilizing timber, a renewable resource, builders can reduce their carbon footprint and promote environmental stewardship.

Furthermore, the manufacturing process of timber LVL formwork consumes less energy and produces fewer greenhouse gas emissions compared to alternative construction materials. This eco-friendly aspect of timber LVL formwork aligns with the growing demand for sustainable building practices and green construction technologies, making it a preferred choice for environmentally conscious builders and developers.

Waste Reduction and Recycling Opportunities

The reusable nature of timber LVL formwork minimizes waste generation on construction sites. Additionally, at the end of their lifespan, LVL sheets can be recycled or repurposed into other wood products, reducing the overall environmental impact.

Moreover, the biodegradability of timber LVL formwork ensures that at the end of its lifecycle, it can naturally decompose without leaving harmful residues in the environment. This cradle-to-grave sustainability approach underscores the importance of choosing materials that not only serve their immediate purpose but also contribute to a circular economy where resources are used efficiently and responsibly.

Durability and Performance of Timber LVL Formwork

Timber LVL formwork not only offers economic and environmental advantages but also ensures long-lasting performance and exceptional durability. The use of laminated veneer lumber (LVL) in formwork construction provides a sustainable alternative to traditional materials, reducing the overall carbon footprint of the project. Additionally, the natural insulating properties of timber help regulate temperature and humidity levels on the construction site, creating a more comfortable working environment for laborers. Find more about humidity at https://scied.ucar.edu/learning-zone/how-weather-works/humidity

Furthermore, timber LVL formwork is known for its versatility, allowing for intricate designs and shapes to be easily achieved. This flexibility in formwork design can lead to innovative architectural solutions and unique building aesthetics, enhancing the overall visual appeal of the structure.

Lifespan and Reusability of Timber LVL Formwork

Timber LVL formwork is designed to be durable and withstand multiple usage cycles. With proper maintenance and care, LVL sheets can be reused for numerous construction projects, further enhancing their cost-effectiveness. The longevity of timber LVL formwork not only reduces the need for frequent replacements but also minimizes waste generation, aligning with sustainable construction practices.

Moreover, the reusability of timber LVL formwork contributes to the circular economy model, promoting resource efficiency and reducing the demand for virgin materials. By incorporating recycled LVL sheets into new formwork systems, construction projects can significantly reduce their environmental impact and promote a more sustainable industry.

Strength and Stability of Timber LVL Formwork

LVL sheets possess excellent strength and stability characteristics, allowing them to support the weight of wet concrete without warping or bending. This ensures the structural stability and safety of the construction throughout the curing process. The dimensional stability of timber LVL formwork minimizes the risk of concrete surface defects, resulting in smoother finishes and higher quality concrete elements.

Additionally, the lightweight nature of timber LVL formwork simplifies handling and installation processes, reducing labor costs and construction time. The ease of assembly and disassembly of LVL formwork systems enhances on-site efficiency and productivity, making them a preferred choice for various construction projects.

Challenges and Solutions in Using Timber LVL Formwork

While timber LVL formwork offers numerous benefits, there are also challenges that need to be considered for successful implementation.

Timber Laminated Veneer Lumber (LVL) formwork is a popular choice in construction due to its strength, durability, and sustainability. LVL formwork is known for its ability to withstand heavy loads and provide a smooth surface finish, making it ideal for various concrete forming applications.

Common Issues in Using Timber LVL Formwork

One common issue in using timber LVL formwork is the risk of moisture absorption, which can lead to dimensional changes and affect the overall strength of the material. Additionally, proper storage and handling practices are essential to prevent damage and ensure the longevity of LVL sheets. To read more about moisture click here.

Another challenge faced when using timber LVL formwork is the potential for warping or bowing of the sheets, especially when exposed to fluctuating environmental conditions. This can result in inaccuracies in the concrete structure and impact the quality of the final construction project.

Overcoming Obstacles in Timber LVL Formwork Implementation

To overcome challenges in timber LVL formwork implementation, employing moisture-resistant coatings and adhering to proper storage guidelines can help mitigate structural degradation. Additionally, comprehensive training and supervision ensure proper handling and minimize the risk of damage during construction.

Regular inspection of the formwork during and after concrete placement is crucial to identify any issues early on and make necessary adjustments. By implementing quality control measures and proactive maintenance practices, the longevity and performance of timber LVL formwork can be significantly enhanced, ensuring successful construction projects.

Conclusion

In conclusion, timber LVL formwork offers a cost-effective and eco-friendly alternative to traditional formwork methods. Its affordability, ease of use, and environmental benefits make it a viable choice for construction projects. By understanding its characteristics, financial advantages, durability, and challenges, builders and contractors can capitalize on the cost-effectiveness of timber LVL formwork while minimizing environmental impact, ultimately contributing to sustainable construction practices.